When it comes to accidents in the workplace, slips and trips are among the most common causes of serious injury. This is especially true in commercial kitchens, where there is a higher risk of food spillages, standing water and other potential hazards. Rubber matting can help create a safer environment by providing workers with a comfortable, non-slip surface to stand on. Rubber matting is also durable and easy to clean, making it an ideal choice for busy kitchens.

However, not all rubber mats are suitable for kitchen and food manufacturing environments. “Natural Rubber is the most popular material for industrial floor matting,” states First Mats director Richard O’Connor, “But mats made with Nitrile will last longer, especially where oil and grease spillages are commonplace.” PCV matting is also suitable for most environments but doesn’t provide the same fatigue-fighting benefits as rubber.

Standing in one spot causes discomfort, such as muscle and joint pains, and prolonged standing can cause serious health issues, including Musculoskeletal Conditions. The softer surface of rubber matting helps to relieve some of these pains while improving blood circulation, which benefits the workers and their employees. In an independent study from 2015, 75% of businesses that used Anti-Fatigue Matting said that staff well-being had improved, and 44% considered matting to enhance productivity.

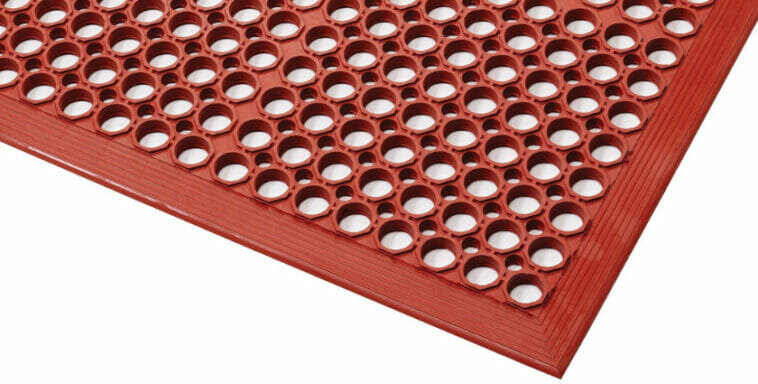

Rubber mats made using Nitrile are often blue or red to help distinguish them from any natural black rubber mats that may also be used on-site. Using mats with a honeycomb or ring pattern is ideal for kitchens, too, as it will help to scrape any food off shoes while allowing spilt liquids to drain safely underneath the mat.

To learn more about matting for commercial kitchens, visit the First Mats website or contact them directly for more information. https://www.firstmats.co.uk/collections/kitchen-catering-mats